History

1973

Foundation of the sole proprietorship Marcel Tanner by Rita and Marcel Tanner. The trained draughtsmen construct various assemblies for mechanical engineering in wage labour.

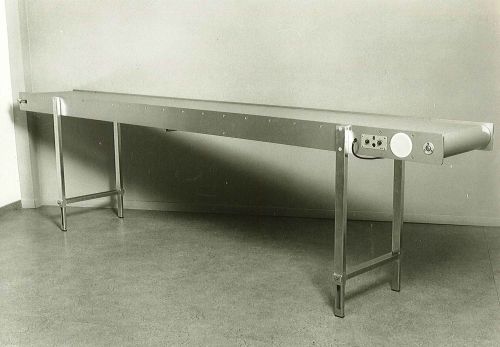

1976

First own assembly work. Smaller conveyor belts – mainly for the food indutry – are produced.

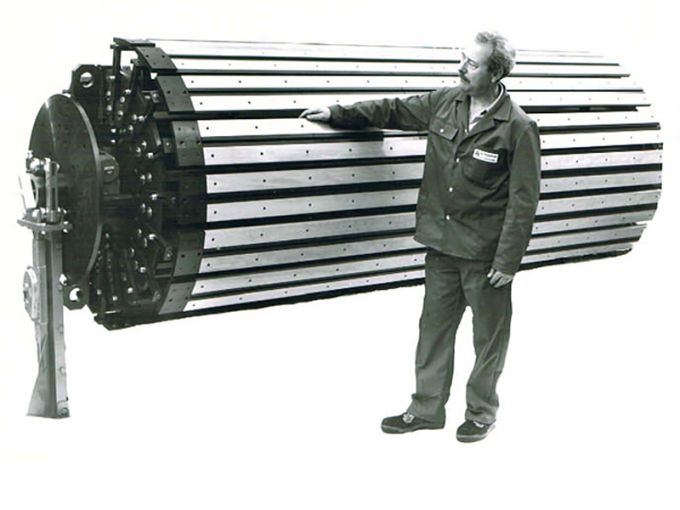

1977

Employment of a design engineer. First contacts for the transformer production concerning insulating apparatus and winding cores (expanding mandrels).

1978

First parts are produced in-house. Employment of a machine mechanice and a machine fitter.

1979

Transformation of the sole proprietorship Marcel Tanner into M. Tanner AG.

1980

M. Tanner AG is active in two areas. Conveying technology and transformer technology. The transformer technology division produces machines and equipment for the manufacture of electrical coils for the production of large transformers and railway motors.

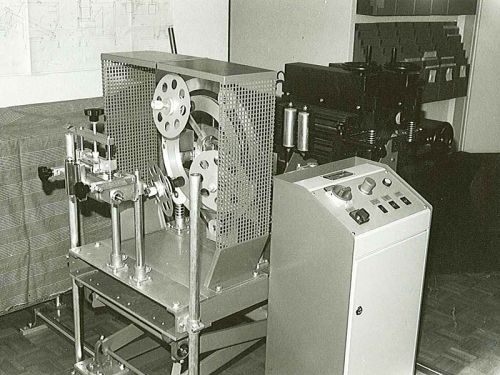

1983

First test trials in the field of PET feeding systems.

1985

First delivery of a feeding system for PET stretch blow moulding machines with a capacity of 1500 preforms per hour.

1986

Relocation of the headquarters of M. Tanner AG from Zurich to Tagelswangen (Lindau ZH) with six employees.

1998

Relocation of the M. Tanner AG headquarters from Tagelswangen to Illnau (Effretikon) with 12 employees.

2001

Around 23 employees work for M. Tanner AG.

2005

Opening of plant 2. M. Tanner AG production moves into larger premises near the main site.

2006

M. Tanner AG has around 65 employees.

2008

Opening of plant 3. The large-scale assembly is now located next to the production (plant 2) in an assembly hall.

2009

The city council of Illnau-Effretikon presents M. Tanner AG with the recognition award for the company of the year 2009. In the meantime, over 2000 PET feeding systems from M. Tanner AG are in use worldwide.

2010

The 1st Tanner clamping conveyor is delivered and put into operation.

2012

Change of management. Marco Tanner replaces his father Marcel Tanner as CEO.

2013

Tanner is installing two new OHT clamping conveyors with overhead rinser at Coca-Cola Hellenic in Austria and at Mosterei Möhl in Switzerland.

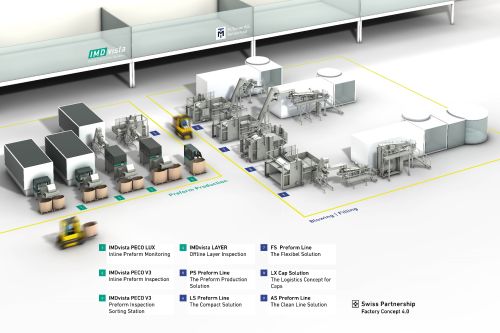

2014

Together with the Swiss company IMD AG, Tanner has several preform feeding systems with inspection systems in operation.

2015

Tanner OHT clamping conveyors with the options camera inspection, overhead air rinser and UVC irradiation are regularly installed worldwide as all-in-one solutions.

2017

With its wide range of products, Tanner is considered the world’s number one contact for preform handling upstream of blow moulders and inspection systems.

2018

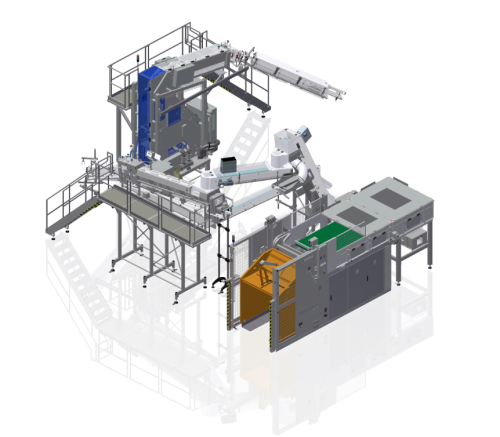

First Tanner AS Preform Line delivered. The high-quality Clean-Line feeding system was manufactured for a German market leader in the dairy industry.

2020

CLEAN LINE: More than 15 installations have already been put into operation worldwide with controlled air exchange (H14 filter) within the complete system..

2021

In September 2021, Tanner modernised a PET filling line for the well-known Swiss beverage manufacturer Rivella and installed an automatic box feeder for loading the preform tipper (with soft handling).

2022

One year before the company’s 50th anniversary, Tanner came up with a world first. The ErgoFlow conveys oriented preforms, driven by two conveyor belts, horizontally into the stretch blow moulder or into the inspection system.

2023

Rita and Marcel Tanner founded the company on

April 1st, 1973. «I am just proud of my parents, who 50 years ago had the courage and determination to become self-employed. A Big Thank You for 50 years of passion and commitment,” says CEO Marco Tanner.

2024

Coca-Cola Europacific Partners in Knetzgau, Germany relies on the latest technology from Tanner. The double soft handling for the preform loading and the floor-level ErgoFlow infeed ensure the top modern preform handling in front of the blow molding machine. Space-saving and efficient, the “Preform Line of the future