Blowing & filling bottles

You produce finished products such as soft drinks, water or other things with your blow-moulder filler block.

Your production

By blocking the blow-moulding machine and the filler, the blow-moulding machine with preform sorting also stands in or directly at the wet area of your production.

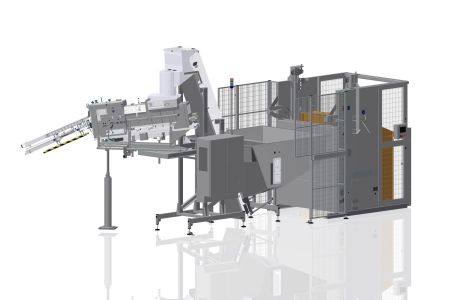

Our Preform Line

Preform Line replaces the single machines tipper & preform feeding.

Where you used to install and commission two autonomous machines, Preform Tipper and Preform Feeder, we now offer a complete solution from one source. One control, one system, one line – the Preform Line.

From the low capacity range (up to 12,000 p/h) to the high capacity range (up to 85,000 p/h) we offer you the right solution for efficient, user-friendly and trouble-free feeding.

Option Soft-Handling

By using a soft handling system you eliminate any drop height of preforms and thus increase the product quality. In addition, the noise during the tipping process is significantly reduced.

Option Hygienic Package

Maximum quality should be achieved in the first process step of your production line.

With the use of a preform internal cleaning system, you ensure the highest possible preform quality at the entrance to the blow-moulder/filler block.

Option Camera Inspection

By using a preform camera inspection, you ensure a trouble-free downstream process by means of automatic ejection of defective preforms before the blow-moulder/filler block.